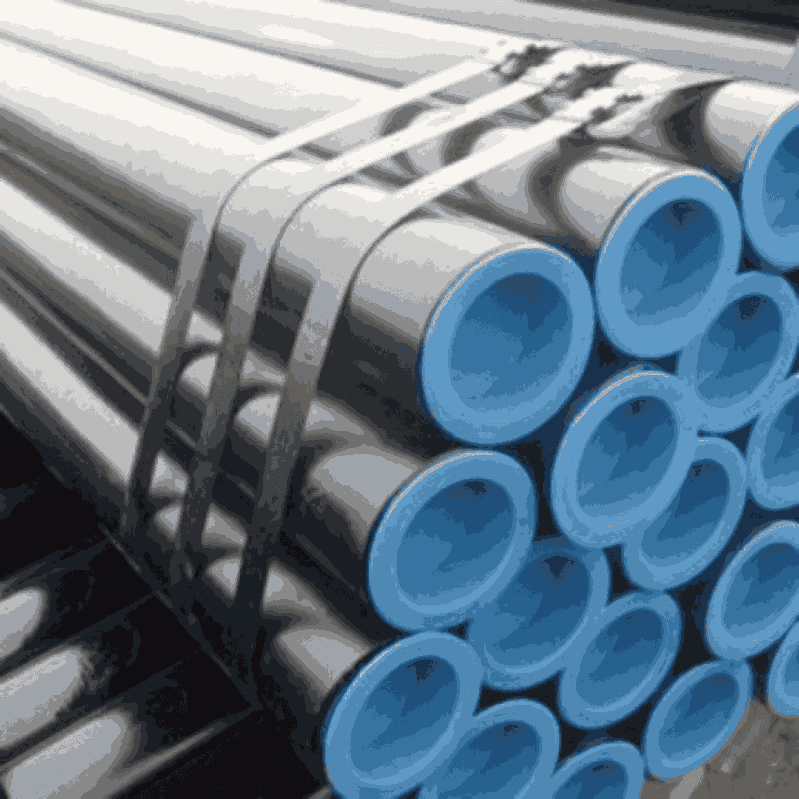

A335 Gr P5 Seamless Pipes

Countries We Export:

Afghanistan, Albania, Algeria, Andorra, Angola, Antigua-Barbuda Argentina, Armenia, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Bosnia-Herzegovina, Botswana, Brazil, Brunei, Bulgaria, Burkina-Faso, Burundi, Côte d’Ivoire, Cabo Verde, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, China, Colombia, Comoros, Congo (Congo-Brazzaville), Costa-Rica, Croatia, Cuba, Cyprus, Czechia (Czech Republic), Democratic Republic of the Congo, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Eswatini (fmr. “Swaziland”), Ethiopia, Fiji, Finland, France, Gabon, Gambia, Georgia, Germany, Ghana, Greece, Grenada, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Holy See, Honduras, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Mauritania, Mauritius, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Morocco, Mozambique, Myanmar (formerly Burma), Namibia, Nauru, Nepal, Netherlands, New Zealand, Nicaragua, North Korea, North Macedonia, Norway, Oman, Pakistan, Palau, Palestine-State, Panama, Papua, New Guinea, Paraguay, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Samoa, San Marino, Sao Tome and Principe, Saudi Arabia, Senegal, Serbia, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Korea, South Sudan, Spain, Sri Lanka, Sudan, Suriname, Sweden, Switzerland, Syria, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Tuvalu, Uganda, Ukraine, United Arab Emirates, United Kingdom, United States of America, Uruguay, Uzbekistan, Vanuatu, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe.

Cities We Supply:

London, New-York, Paris, Moscow, Tokyo, Dubai, Singapore, Barcelona, Los-Angeles, Madrid Rome, Chicago, Toronto, San-Francisco, Abu-Dhabi, St-Petersburg, Amsterdam, Berlin Prague, Washington,Istanbul, Las-Vegas, Doha, Seoul, Sydney, Beijing, Miami, Munich, Milan, San-Diego, Bangkok, Vienna, Dublin, Vancouver, Boston, Zurich, Melbourne, Budapest, Houston, Seattle, Montreal, Hong-Kong, Frankfurt, Sao-Paulo, Tel-Aviv, Copenhagen, Calgary, Orlando, Atlanta, Dallas, Hamburg, Osaka, Lisbon, Austin, Phoenix Naples, Oslo, Denver, Stockholm, Riyadh, Delhi, Buenos Aires, San-Jose, Brussels, Portland Philadelphia, Ottawa, Helsinki, Valencia, Brisbane, Warsaw, Minneapolis, Shanghai, Lyon, Adelaide, Edmonton, Marseille, Muscat, Athens, Stuttgart, Rio-De-Janeii, Baltimore, Auckland, Cologne, New-Orlean, Kuwait-City, Kiev, Hanover, Perth, Minsk, Bucharest, Nashville, Dusseldorf, Manchester, Sacramento, Glasgow, Mexico-City, Salt-Lake-Ci, Raleigh, Cracow